Description

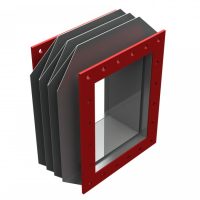

Glass Fibre expansion joints are often used in ducts which carry hot gases at low pressures. The major design parameters are the temperatures and flow rates of the gases and the amount and abrasiveness of solids suspended in the gases. Layers of different fabrics insulation can be combined to accommodate the temperatures and pressure in the system. The fabric belt may need to be replaced periodically.Fabric Expansion Joints are non-metallic duct expansion joints that provide stress relief for piping and ducting systems by absorbing thermal growth and shock, isolating mechanical vibration, and allowing for misalignments.Fabric expansion joints are precision engineered specifically for your application.duct expansion joints are custom engineered to handle low pressure (±3 psig) applications with temperatures ranging from -100°F to more than 2000°F.Service Features of Fabric Expansion Joints Absorb axial, transverse and torsional movements Corrosion and chemical resistance Negligible spring rates and loads Easily repairable and installable High cycle life Unique application solutions Vibration dampening and sound attenuation More movement in shorter face-to-face Less force to flex than metal expansion joints Excellent corrosion and chemical resistance Temperature capability range (-110°F to more than 2,000°F) Lower shipping and installation costs Variety of flexible belt materials available: Single-layer and composite belts Elastomers have excellent abrasion resistance Custom designed for each specific application

Reviews

There are no reviews yet.