Description

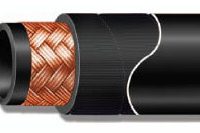

Modern hydraulic hose typically consists of at least three parts: an inner tube that carries the fluid, a reinforcement layer, and a protective outer layer.The inner tube must have some flexibility and needs to be compatible with the type of fluid it will carry. Commonly used compounds include synthetic rubber, thermoplastics, and PTFE, sometimes called Teflon. The reinforcement layer consists of one or more sheaths of braided wire, spiral-wound wire, or textile yarn. The outer layer is often weather-, oil-, or abrasion-resistant, depending upon the type of environment the hose is designed for.Not surprisingly, hydraulic hoses have a finite life. Proper sizing and use of the correct type of hose will certainly extend the life of a hose assembly, but there are many different factors that affect a hose’s lifespan. SAE identifies some of the worst offenses as:flexing the hose to less than the specified minimum bend radiustwisting, pulling, kinking, crushing, or abrading the hoseoperating the hydraulic system above maximum or below minimum temperatureexposing the hose to rapid or transient rises (surges) in pressure above the maximum operating pressure, andintermixing hose, fittings, or assembly equipment not recommended as compatible by the manufacturer or not following the manufacturer’s instructions for fabricating hose assemblies.